IV Solve Tutorial

Aim: To design and build modular, organization devices for patient tubing lines

Estimated time: 60 minutes

Technical skill building: hands-on prototyping, shaping thermoplastics and moldable materials

Materials & tools: Gear Tie, Instamorph, Legos, Sugru, Zip Tie, Silicone Tape

Learning Objectives: To go from idea, to sketch, to prototype in less than 60 minutes.

What's in the Kit

Things that Shape + Form

Instamorph

LEGOS

MEdium DeNSITY Foam

Gear Ties

Sugru

Things that Attach

HOt glue

Assorted plastic clips + Clamps

VELCRO

NYLon cord

Zip-ties

Ideas to get you Started

Gear Ties

What it can do: Flexible forming of thin parts

What it is useful for: Temporary attachments, Parts that need to be easily modified or re-formed, Waterproof applications

When to use other materials: Permanent solutions or attachments, Weight bearing applications

How to use it:

Examples Shapes:

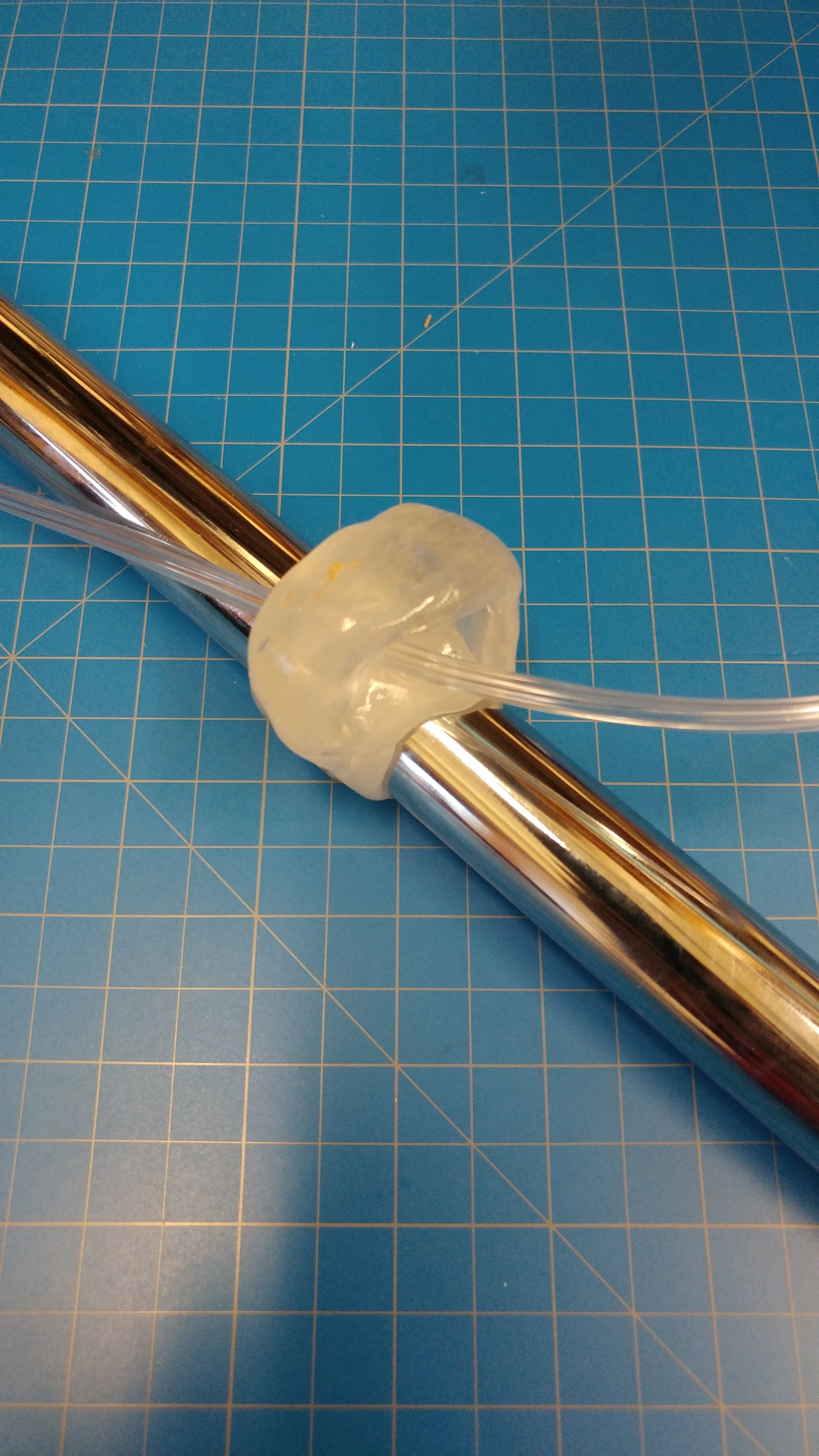

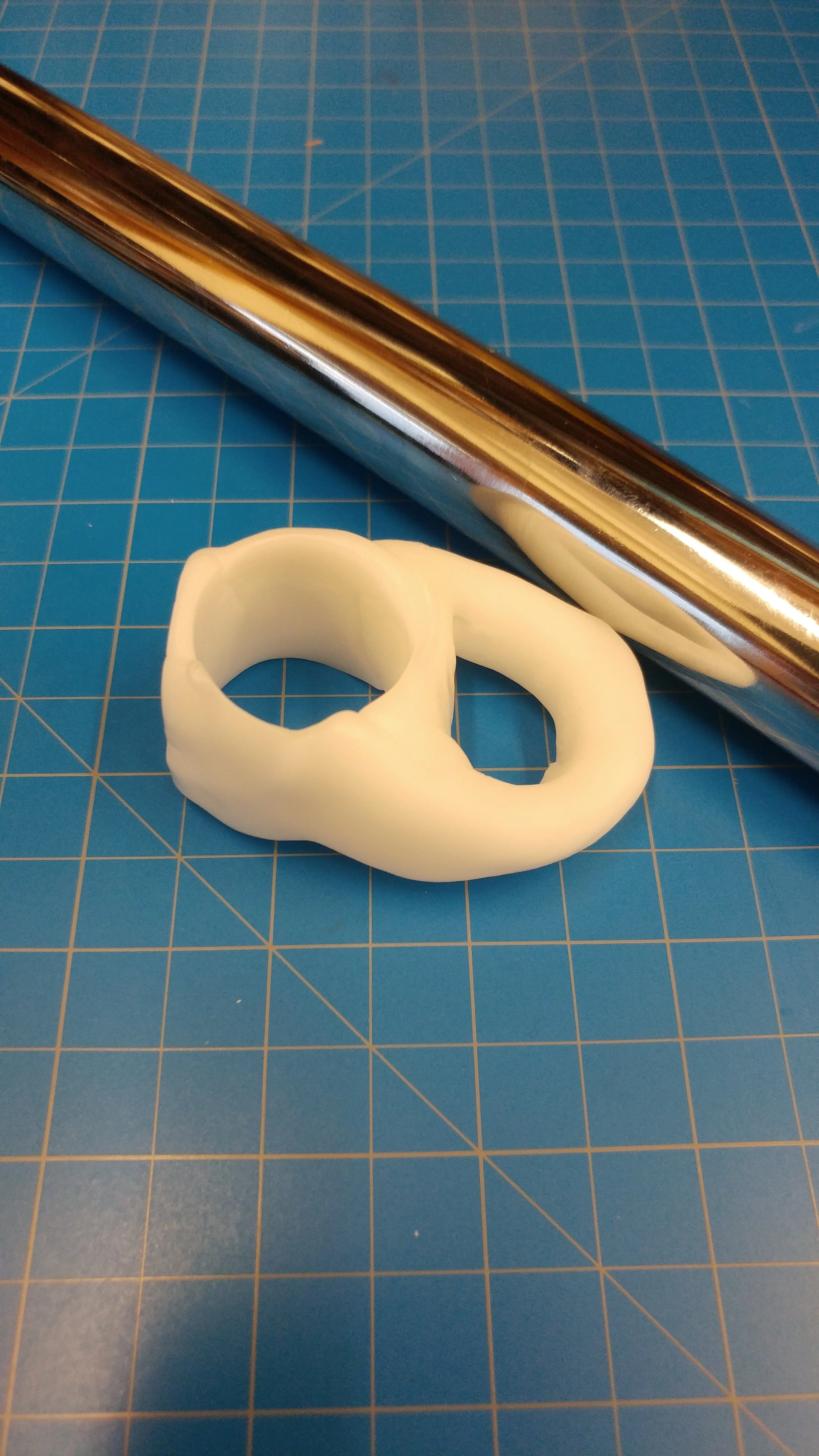

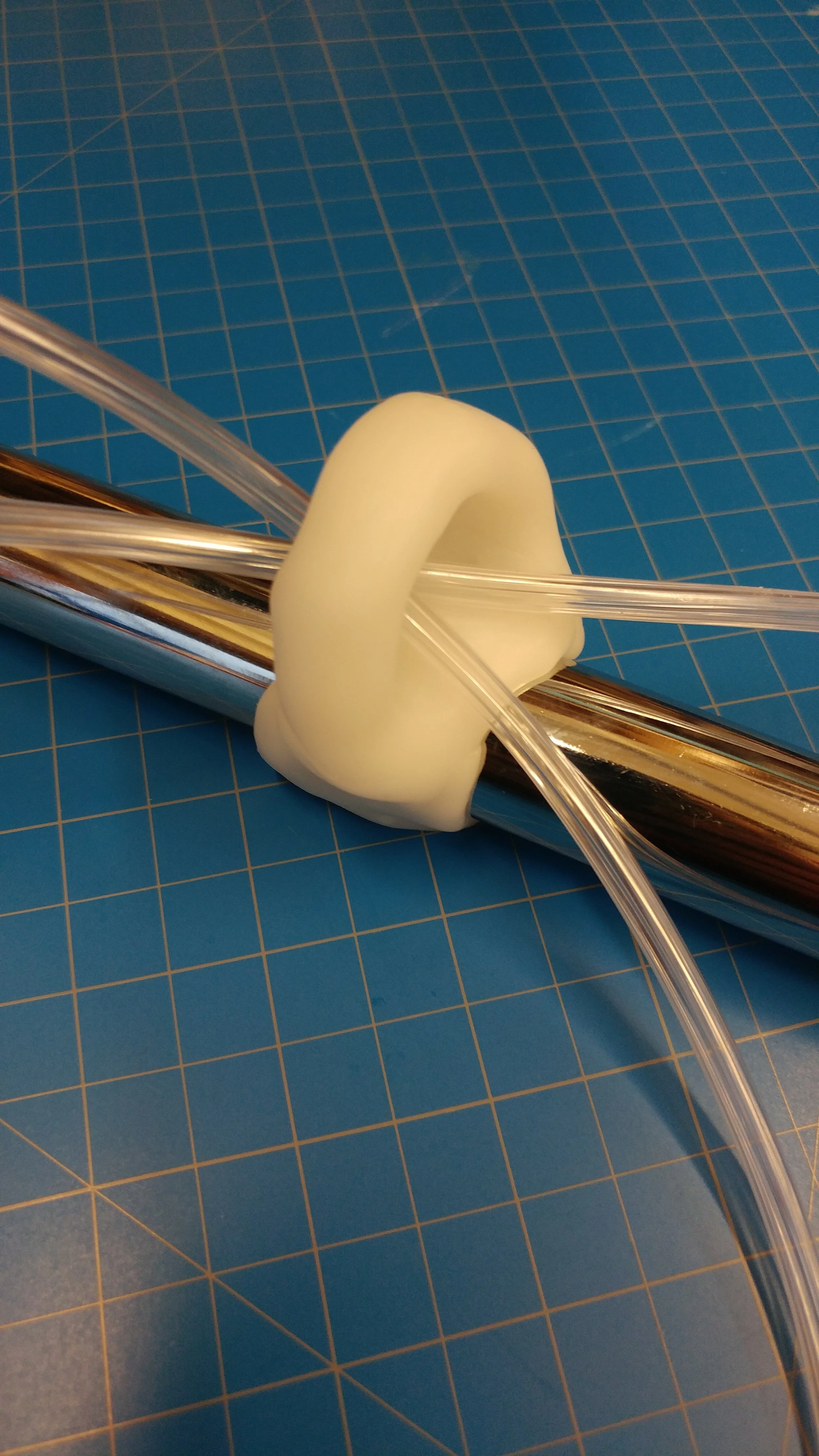

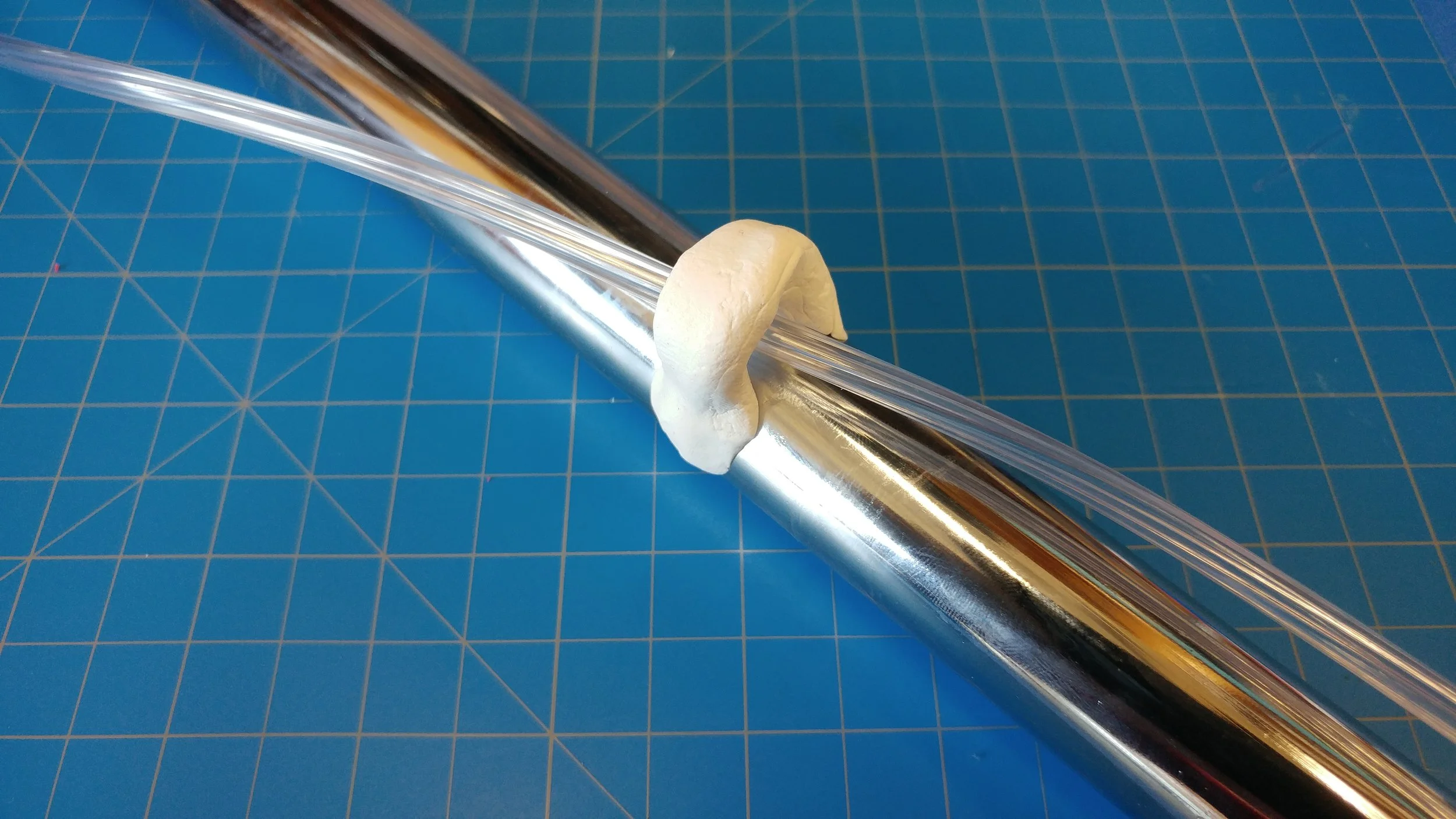

Instamorph

What it can do: Create custom shaped parts

What it is useful for: Permanent rigid parts (attachments or modifications), Applications where durability is required, Reusable material, Waterproof applications

When to use other materials: Flexibility is required, Applications where a solution needs to be quickly modified

How to use it:

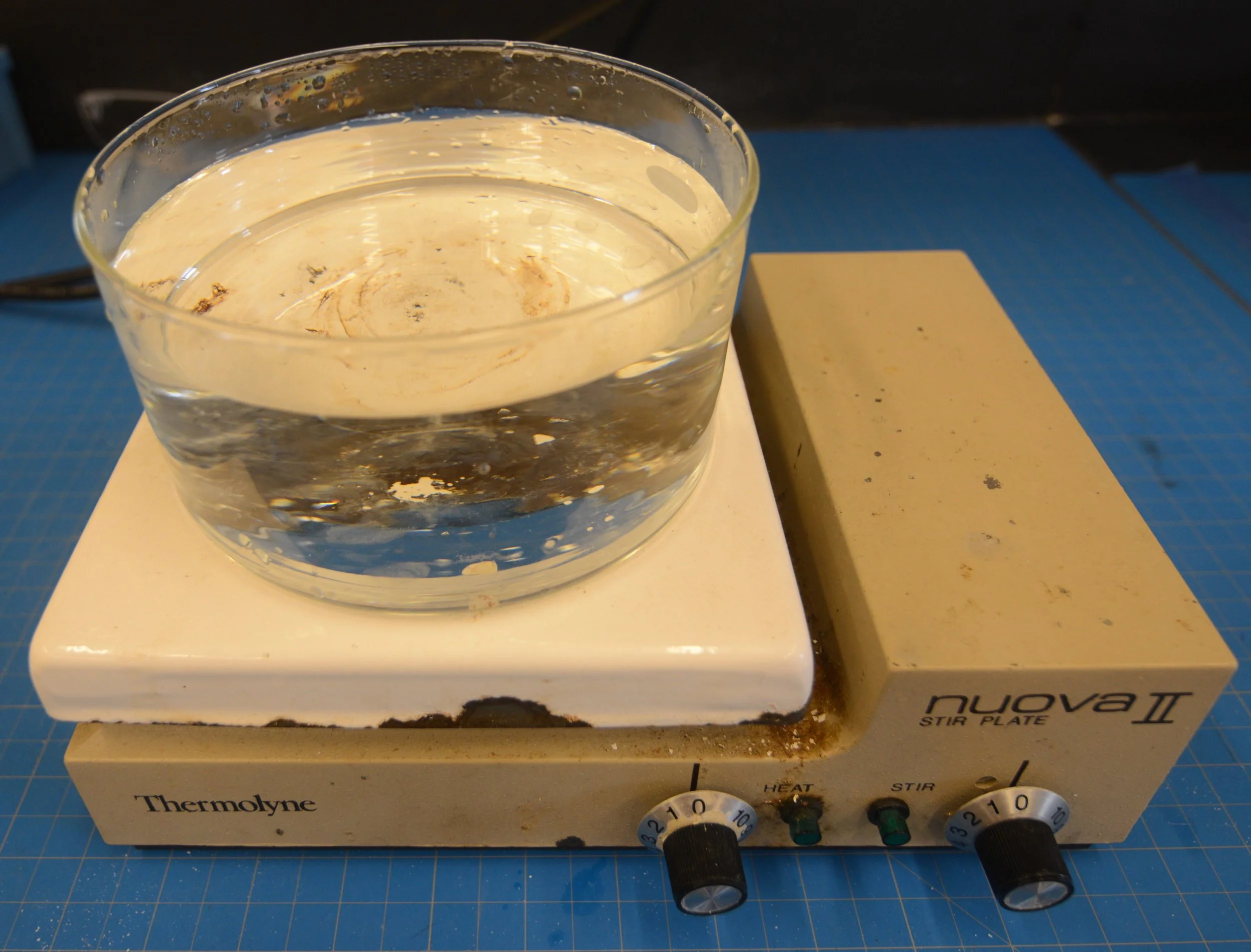

1. Heat water to 140°F/60°C or higher. For this example, a hot plate was used, but a mug in a microwave or pot on a stovetop are similarly effective.

2. Handle the container carefully once the water is heated. Place on a flat surface. When ready, pour the Instamorph into the hot water.

3. As the Instamorph heats up, the pellets will start to turn clear. Once all of the pellets are clear, wait 30 seconds, then using tongs or a similar tool knead the pellets together.

4. Remove the pellets from the hot water. Be careful when handling the Instamorph as it is still warm. Heat resistant glove work well. In the absence of gloves, paper towels will suffice. Knead the pellets by hand into the desired shape. If you are having trouble shaping the Instamorph, you may need to reheat the material.

5. While clear, form the material around an object if desired.

6. As the material cools, it will turn back into the milky white color of the original pellets. Once it hardens, you will need to repeat Steps 1-3 to re-shape the Instamorph.

Example Uses:

Legos

What it can do: Create custom shapes and structures that can be easily modified

What it is useful for: Quick, modifiable concept prototyping of custom parts

When to use other materials: Final solutions or prototypes, Applications where an organic or irregular shape is desired

How to use it:

Example Uses:

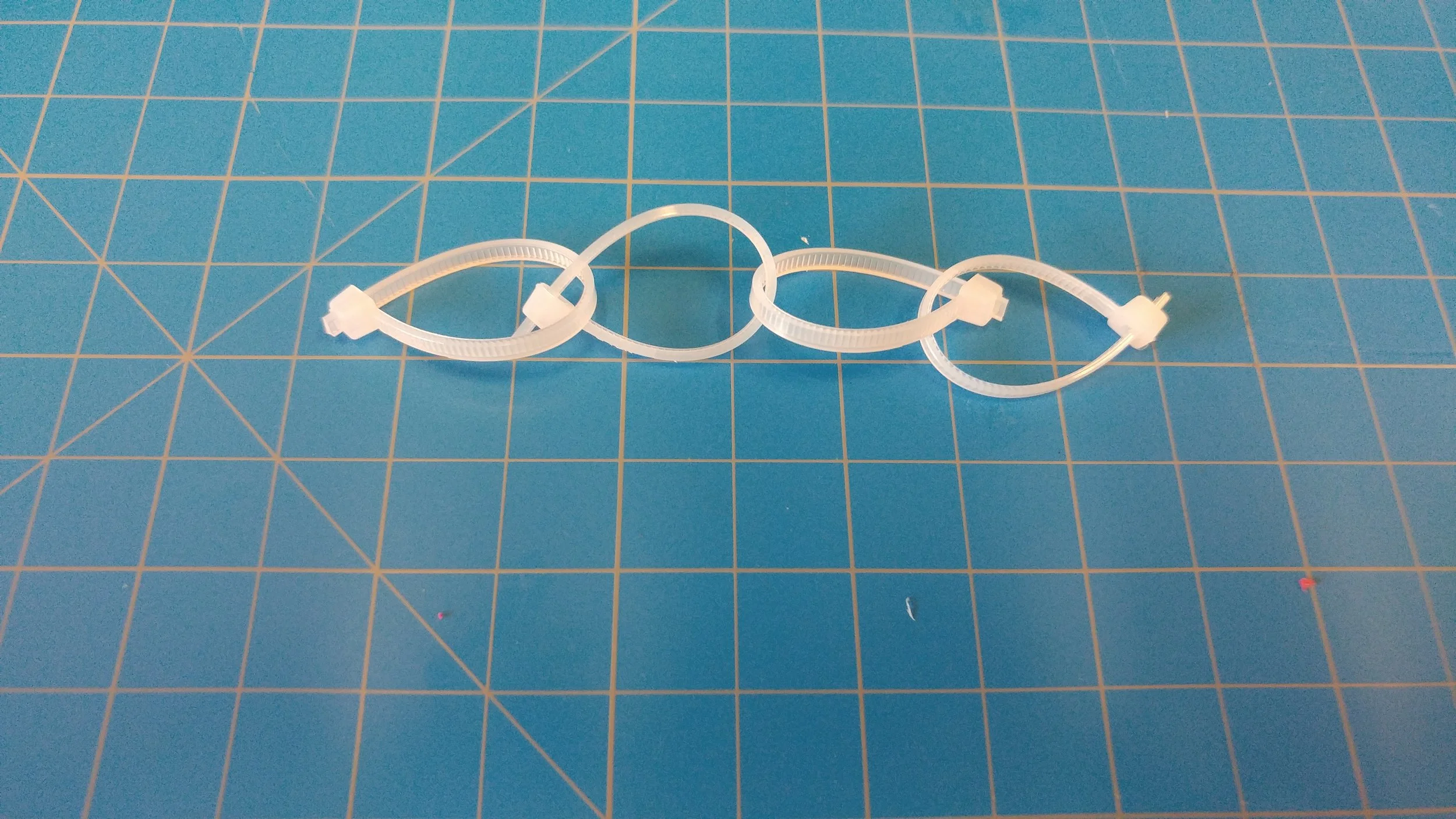

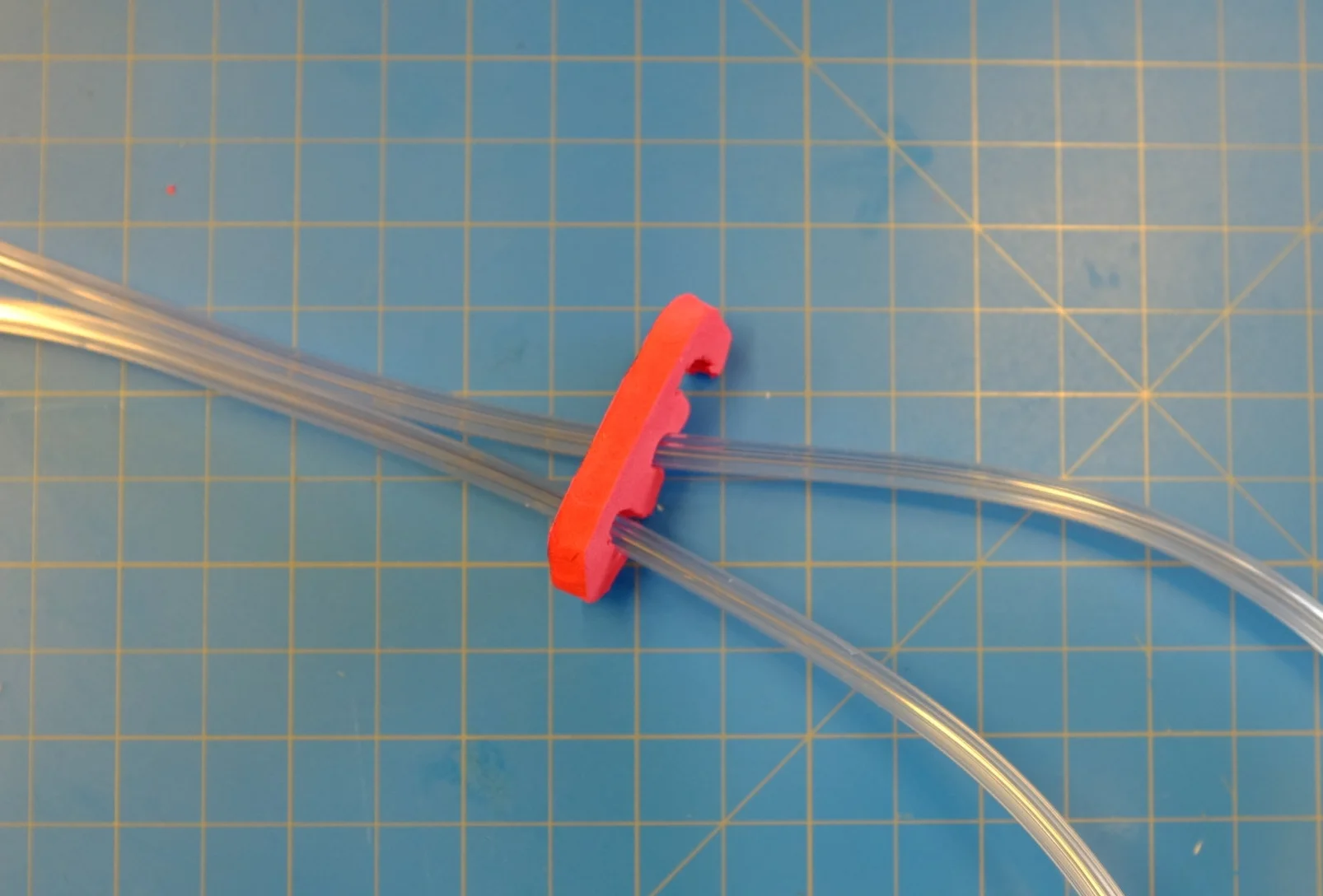

Zip Ties

What it can do: Secure two or more parts together

What it is useful for: Semi-permanent connections and attachments (very durable, but can be easily removed if needed), Low-cost applications, Holding objects in place

When to use other materials:

How to use it: Simply pull the end of the zip tie through the inner-facing flat side of the head and tighten as needed

Example Uses:

Sugru

What it can do: Small permanent parts

What it is useful for: One time uses, Small parts and fixes, Waterproof applications, Attaching two small parts

When to use other materials: Re-usability of materials is important, Flexible parts, Medium to large parts

How to use it:

1. After removing the Sugru from the package

2. Form the Sugru into the desired shape and apply it to the surface as necessary

Example Uses

Medium Density Foam

What it can do: Used to create custom soft and flexible parts

What it is useful for: Cushioning parts, Quick prototypes when a soft, flexible material is desired

When to use other materials: Rigidity is required, a durable solution is needed, Waterproof applications

How to use it

Example Uses

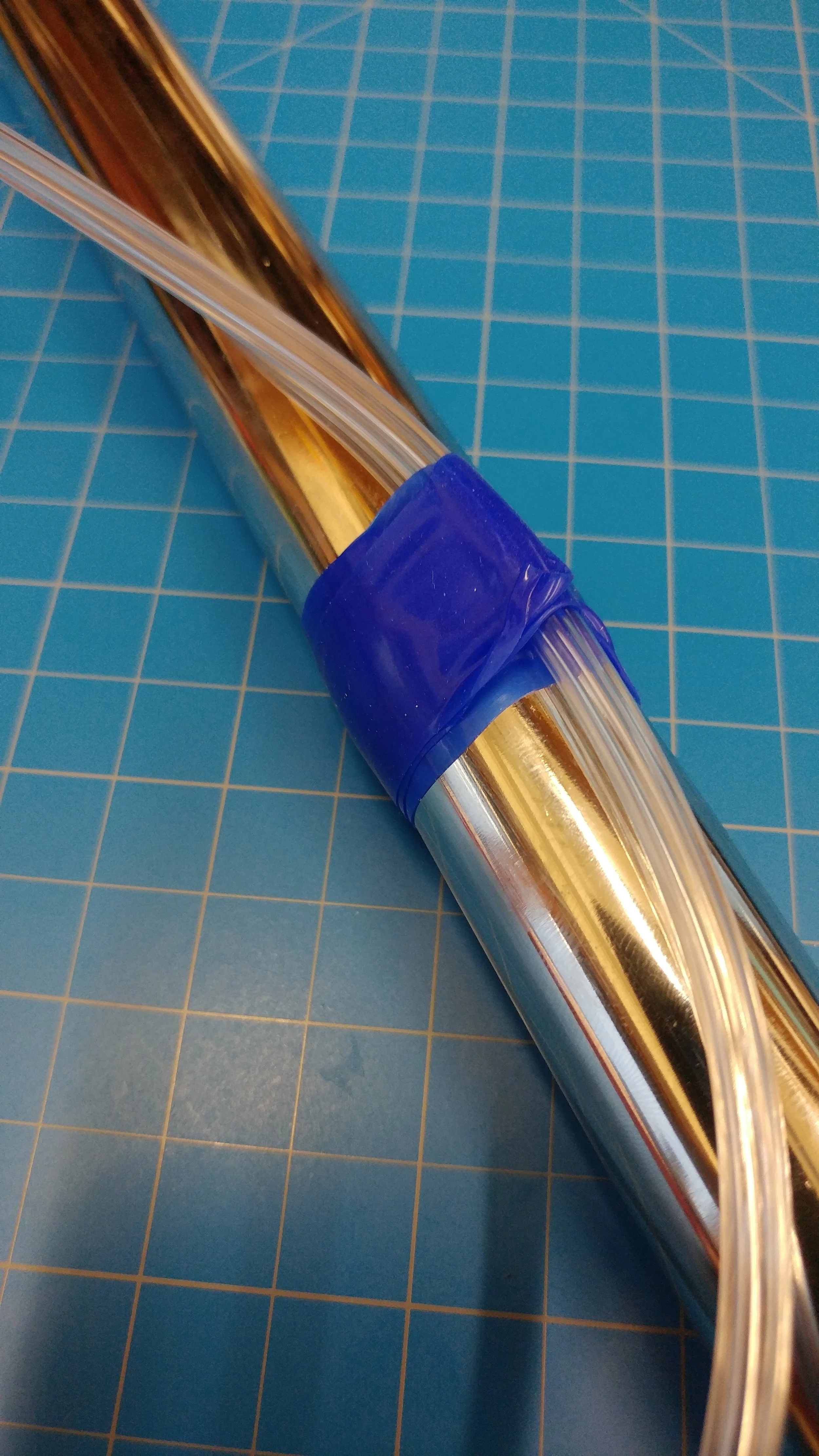

Silicone Tape

What it can do: Material that self-fuses, providing a watertight seal that can withstand high pressures

What it is useful for: Repairs of tubing, Combining and connecting tubing,

When to use other materials: When a non-permanent prototype is needed

How to use it: Wrap the tape around an object, as it overlaps, it will self-fuse creating a strong permanent bond, the further it is stretched and tighter it is wrapped, the stronger the bond

Example Uses